TopIndustries offer the push pull slip sheet model for efficient and safe pallet-less handling of bagged foods or fruits or beverages and corrugated boxes. The push-pull tool is an ergonomic solution. It makes loading and unloading pallet-less or pallet loads without the need for demanding manual labor. The push-pull device offers great flexibility as it can be applied in different industries ranging from cold storage to retail items and transporting bags or containers. It is available in different dimensions and if you don’t find the correct size then have it easily customized. Use the machine to load containers that need slip sheets during overseas shipping.

Slip sheets are discs of plastic or cardboard that are dragged or pressed over the goods. When the truck reaches the destination, the slip sheets underneath products help to push-pull while handling.

The equipment is designed with a holding slip-sheet mechanism. It is a feature, which helps to empty containers without disturbing the slip sheet. So, the reusable slip sheets can be used again, thus reducing shipping costs.

The push-pull slip sheet is an economical material handling solution. Wooden pallets are bulky and take up plenty of space. The pull-push sheet is lighter, cheaper, and consumes less space than wooden or plastic pallets. Slip sheets are great for storing, transporting/moving and shipping goods placed in bags and boxes. The slip sheets are eco-friendly as recycled material is used to design them but the attachment to use them is specially designed.

Reasons to invest in slip sheet arrangement

- Replaces labor-intensive manual tasks.

- Saves significantly on transportation costs because slip sheets allow loading 17% more onto a truck in comparison to pallets. It means if you send 100 trucks of the same volume using wooden pallets then using slip sheets will help to reduce the number of trucks to 90. What a difference!

- A slip sheet is 10X slimmer than a wood pallet. It means 1,000 sheets will need 1 m³ space, while the same amount of wooden pallets needs 70 m³. Thus you can save waste on single-use wooden pallets.

- Reduces the potential of damaged products.

- Increases the container’s shipping volume because of its slim nature there is less space needed than pallets.

- Versatile handling solution as it is useful in multiple sectors.

- Integrate the slip sheet seamlessly into the existing inline exchange system.

- Not using pallets but slip sheets allow for saving more space inside the trailers or containers while shipping.

- Slip sheets are 80% cheaper than wooden pallet options. The wooden pallet is 20X heavy and 150X taller in comparison.

- Omitting pallets makes more storage space available in the warehouse.

- The equipment is durable and serves the facility for the long term.

- The attachment has intense pull force, so operates quickly and efficiently.

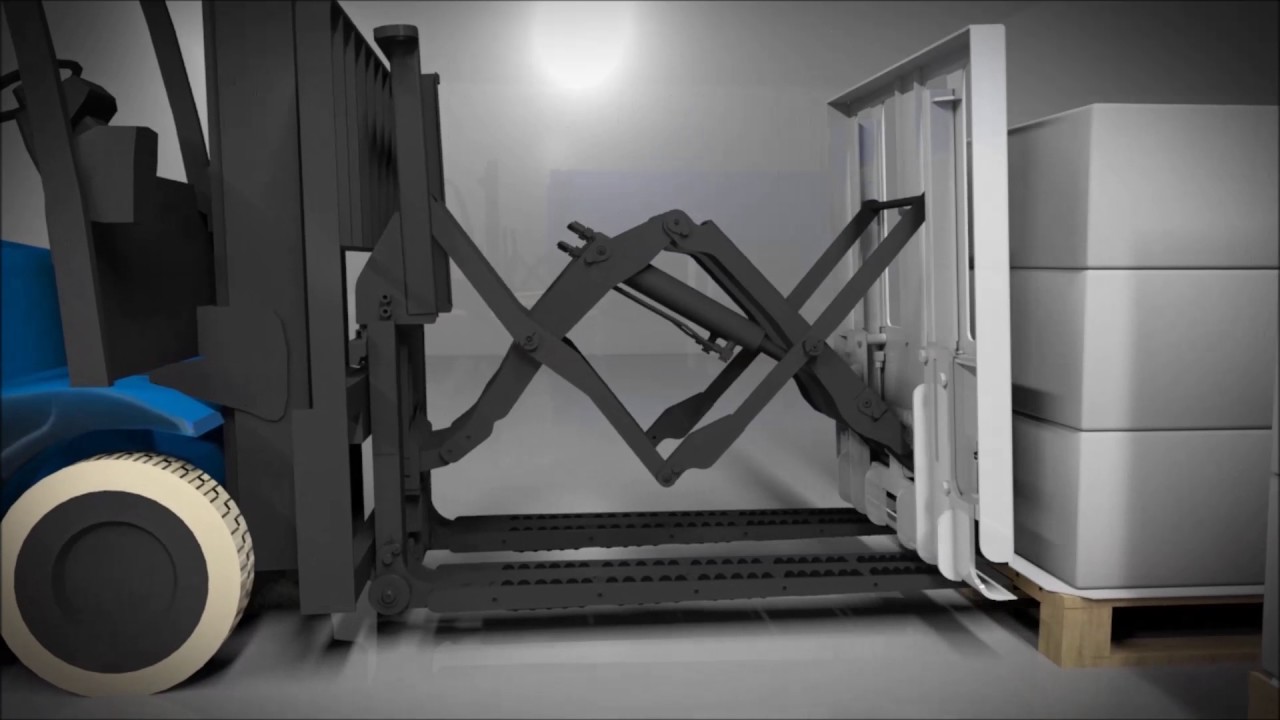

How does the push-pull attachment work?

Push-pull attachment swaps the standard forks. It is connected to the forklift with a hydraulic pipe. Attach the push pull attachment and you are ready to work with slip sheets. The gripper and its face plate are turned out to hook the channel on the slip sheet pallet.

The slip sheet pallet is pulled by the faceplate onto its flat forks. The forklift is loaded and prepared to transport. Unloading works similarly. The slip sheet pallet is pushed onto the truck or containers and the goods are prepared to ship.

Check videos about how push-pull attachment works with slip sheets on TopIndustries.com and even follow on Twitter or Facebook!