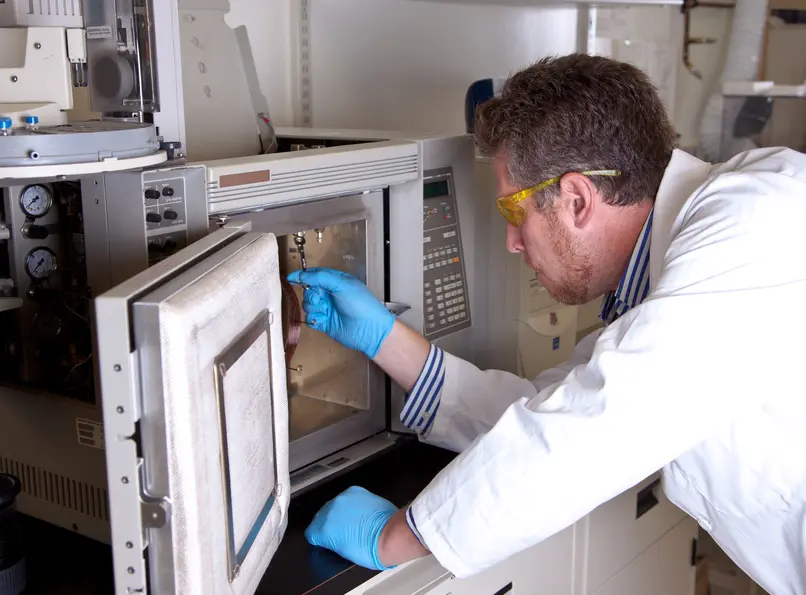

Pharmaceutical ovens or Pharma ovens are advanced machinery used for drying substances in labs and the pharmaceutical industry. They are utilized for dry herbs, granules, and powder.

LeDAB vacuum ovens are available in different sizes, designs, and features. They are capable of performing various types of functions depending on their design.

Types Of Pharmaceutical Oven

Pharmaceutical ovens are distinguished based on size, function, working model, design, application, and technology. The common kinds of pharmaceutical ovens are as follows.

- Laboratory ovens

Laboratory ovens are smaller in measurement. They are used in labs for drying and sterilization purposes.

- Industrial oven

Industrial ovens are enormous and have advanced features. With the help of their high-tech properties, they can perform several tasks in pharmaceutical companies.

- Vacuum ovens

These ovens are used for processing batches. They are utilized for processing metallic medical components. Additionally, they do not have gases in their chambers and are considered for heat treatment, brazing, and case hardening procedures.

- Reach-in ovens

These ovens contain a uniform heating system as the airflow in their shelves is done horizontally. It is used for drying things that need more than a hundred air exchanges every hour. They’re also used for drying other applications with fewer air exchanges in the industry.

- Clean process oven

These types of ovens have high temperatures that range way above 260°C. They are used to manufacture equipment used in healthcare.

- Burn-in ovens

These are particular kinds of ovens that are useful in producing electronic parts. These ovens have average temperatures ranging from 260°C. In these ovens, nitrogen gas is circulated in the air.

Components of Pharmaceutical Ovens

A pharmaceutical oven is composed of different parts that play different roles. These parts decide the design and technologies used so they can be classified further.

- Heat sources

It is essential to provide a heat source for drying the material inside the oven. The sources can be electricity, infrared heat, or vapors. The type and degree of heat are dependent on the type of pharmaceutical oven and the purpose for which it is being used.

- Auto-control system

It is crucial to exercise a certain amount of control over the process to get the desired result so that the materials are dried perfectly. Many ovens have computerized control systems to decide the heat and temperature inside them. It is mainly helpful in drying the material inside the oven without changing the original content. These organs come with control panels that facilitate temperature adjustment to ensure that the process is taking place optimally. These panels help decide temperatures and set timers depending on the user’s needs.

- Pharmaceutical oven tray

These days contain all the substances that are going to be dried out by the oven. The number of trays depends on the type of oven and its design.